DIAMOND LIKE CARBON (DLC)

DLC coating (Diamond-Like Carbon coating) is a special protective layer, also referred to as amorphous carbon. DLC is made with a chemical vapor deposition technique. The chemicals are deposited in a vacuum environment with the help of an inert gas that places the carbon atoms on the surface. They form a thin layered plating of diamond crystal mixed with carbon atoms. Besides its decorative function, the DLC coating is distinguished above all by its inalterability, resistance to corrosion, high hardness and very low coefficient of dry friction which provides excellent scratch resistance. This blend results in an extremely durable treatment with an anthracite color that has been in use for over 20 years in various fields such as Formula 1, power generation, aerospace, the medical sector and since recently; in wrist-watches.

Available on:

Essential Dark Hours,

Vision Shine Carbon

ION PLATING HARDENED (IPH)

An IPH coating, or "Ion Plating Hardened", is actually produced using an ion plating method commonly known as "Physical Vapor Deposition" (PVD). The process consists of depositing on the surface of the watch, a hard but thin dense layer of metal consisting of steel, titanium, ceramic and an alloy of the nickel-copper family. The coating provides long lasting protection against the inevitable scratches and wear marks that affect the aesthetic appearance of the watch. It also provides excellent resistance to corrosion.

Available on:

Vision Shine Moon,

Vision Classic Silver,

Essential Light Hours

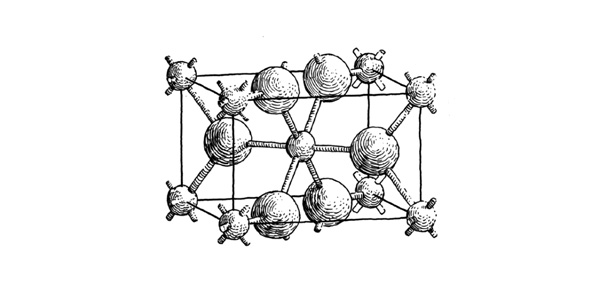

PHYSICAL VAPOUR DEPOSITION (PVD)

Physical vapour deposition (PVD) is a surface treatment adapted from industrial use for metallic coatings in watchmaking. The process consists of applying one or more layer of titanium nitride (a metal, just as hard as it is dense) to the stainless steel. Physical vapour deposition is carried out in a vacuum chamber at temperatures between 150 °C and 500 °C, by means of a cathodic arc source and can react with various gases to deposit oxides, nitrides, carbons or carbonitrides. The titanium coating is then covered again with a coating so that it assumes a hue similar to that of 23.5 karat gold or even carbon. PVD enables colorations that are not subject to deterioration and significant enhancement of resistance against wear.

Available on:

Vision Classic Champagne,

Vision Classic Gold,

Vision Shine Electron

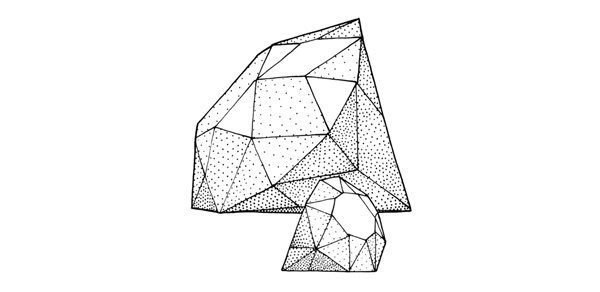

SAPPHIRE GLASS

Sapphire glass is an oxide corundum crystal, cut from a single mass of synthetic sapphire. It takes between 14 to 20 operations to cut a sapphire crystal and obtain its final form. The hardness measures 9 on the Mohs scale, or 1,800 Vickers, which can only be surpassed by the hardness of a diamond. The main properties of sapphire crystal are its durability and virtually scratchproof nature. Due to its extreme resistance to scratches, it allows the watch to maintain its beautiful appearance for much longer. The crystal is also coated with an anti-reflective coating deposited on both faces of the glass. Several ultra-thin layers of metal oxides are deposited successively and reduce the amount of reflections on the crystal's surface. Not only does this enhance the beauty of the dial, but increases the functional purpose of the watch by increasing the dial's readability.

Available on:

Vision Classic Silver,

Vision Classic Champagne,

Essential Dark Hours,

Essential Light Hours,

Vision Shine Electron,

Vision Shine Moon,

Vision Shine Carbon,

Vision Classic Gold

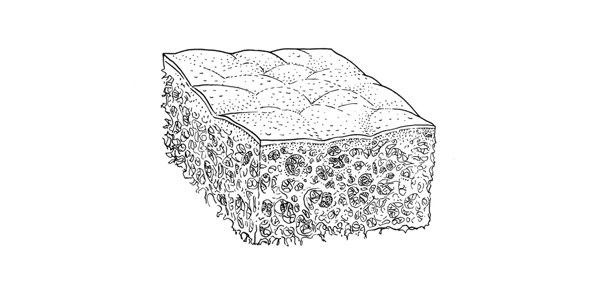

ITALIAN LEATHER

Our finely worked leathers come from the best Italian tanning workshops. Their unique process ensures beauty, durability and strength. The calf leather bracelet is soft and smooth and the leather padding provides better resistance to moisture. The inside of the bracelet is tanned naturally, making it hypoallergenic and the velvety feel is remarkably soft to the touch.

Available on:

Essential Dark Hours,

Essential Light Hours

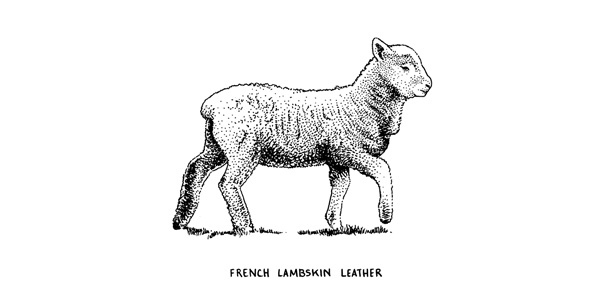

FRENCH LAMBSKIN

The dipped lambskin comes from a master tanner/tawer based in the Centre-Val de Loire region since 1863. The hide comes from a young lamb and is characterised by its very fine grain and softness to the touch. The dipped leather undergoes a process of immersion dyeing which gives it its unique colour.

A fixative is also used so that the leather retains its colour. The skin is usually very fine so as to preserve the fine, soft feel.

Only the very best hides undergo this treatment, which is why they are much prized by craftsmen and the leading brands of luxury goods.

Available on:

Vision Classic Gold,

Vision Classic Champagne,

Vision Classic Silver,

Vision Shine Electron,

Vision Shine Moon,

Vision Shine Carbon

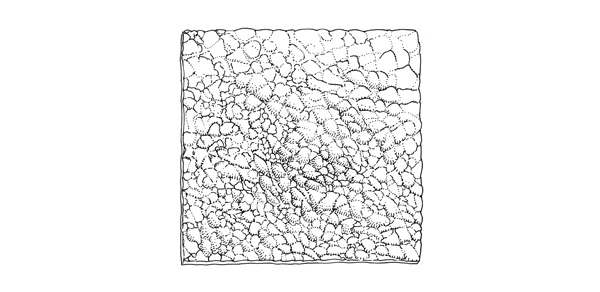

FRENCH CALFSKIN

The calfskin comes from an old tannery established in Romans-sur-Isère since 1803. The full-grain calfskin is carefully selected for fineness, evenness and a smooth grain. The leather is much sought-after for its suppleness and long lasting quality.

Available on:

Vision Shine Carbon,

Vision Shine Moon,

Vision Shine Electron,

Vision Classic Gold,

Vision Classic Silver,

Vision Classic Champagne

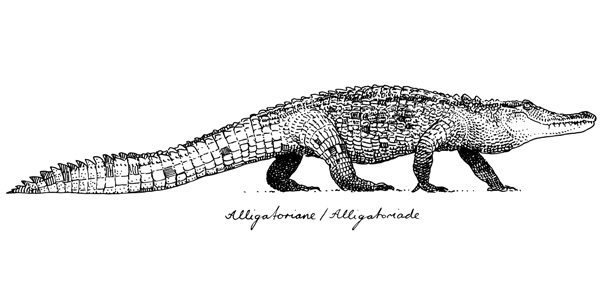

LOUISIANA ALLIGATOR

The Louisiana alligator is selected by hand and self-coloured by an Italian tannery in the Piedmont region. There are no fewer than fifty successive stages in its preparation: soaking, bleaching, shaving, and even polishing the skin. The resulting leather is aesthetically perfect and inimitable. The square scales are especially prized by craftsmen for making luxury goods. The alligator’s flanks are polished with an agate stone to give them a semi-gloss finish.

Our workshops comply with the animal treatment charters established by the relevant authorities.

Available on:

Vision Shine Carbon,

Vision Shine Moon,

Vision Classic Gold,

Vision Classic Silver